Die Casting in Malaysia: A Thriving Industry for Precision Manufacturing

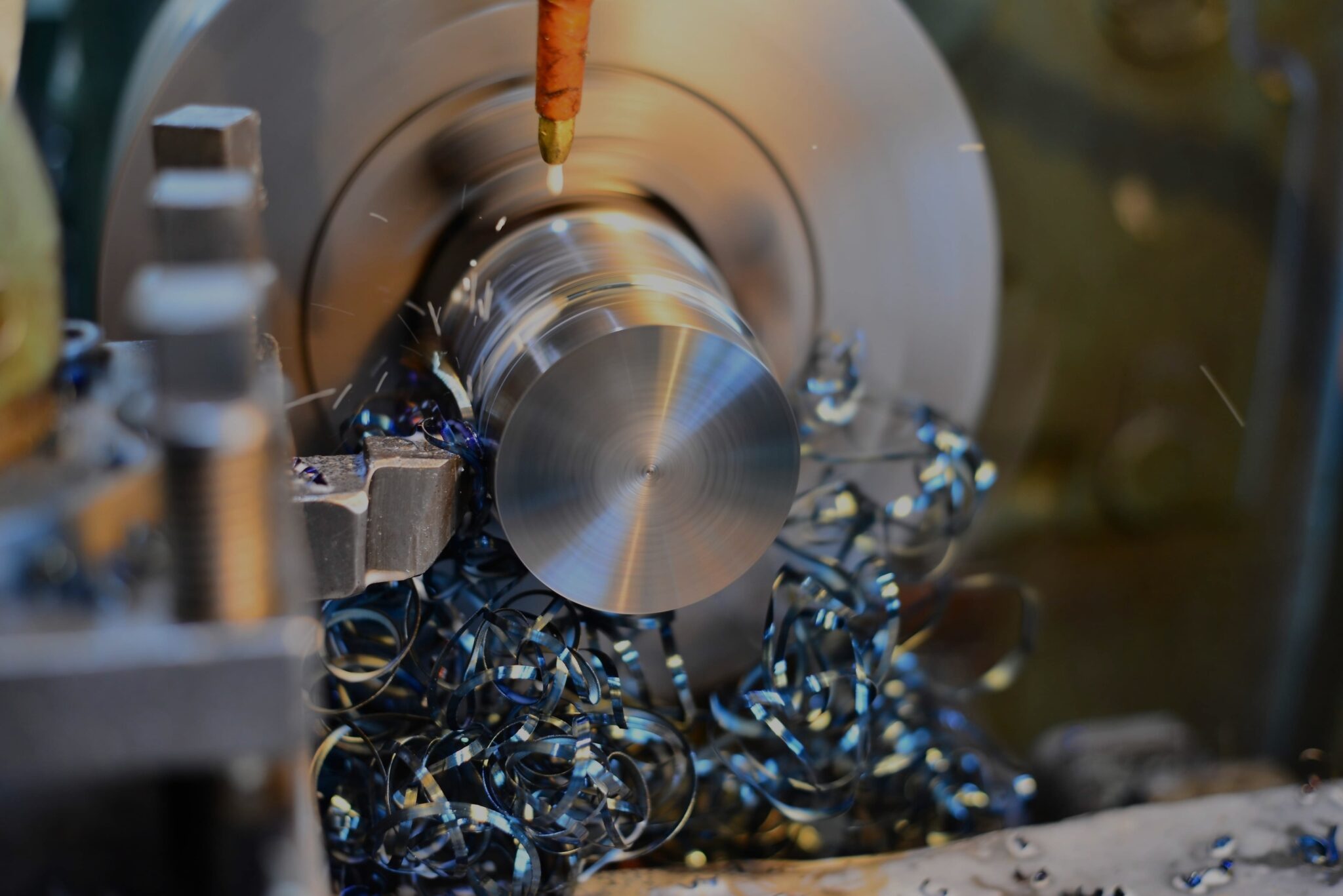

Die casting Malaysia has developed into a major industry, and plays an important role for the nation's manufacturing and industrial sectors. This method, which involves injecting molten metal into molds to create precision metal components, is now a necessity for various industries such as electronics, aerospace, automotive, and consumer goods. Malaysia has become an international hub for top-quality die casting thanks to its highly skilled workforce, state-of-the-art technology, and strategic location in the global supply chain. Many international companies have set establishments in Malaysia, leveraging the country's experience in the field of metal casting and engineering. Die-casting demand is growing as companies look for cost-effective, durable precisely-formed metal parts to make their products. As technology advances the die-casting industry in Malaysia is predicted to continue growing and adopt new technologies to enhance efficiency and sustainability.

The automotive industry is one of the biggest customers of die-cast parts in Malaysia manufacturing companies relying on this method to make robust and lightweight parts. Die-cast zinc and aluminum parts are extensively used in automobile production due to their strength as well as their light weight and the resistance to rust. Parts for transmissions, engines brackets, structural parts are among die-cast components that contribute to the overall performance and efficiency of contemporary automobiles. Because of Malaysia being the home of some significant automotive companies and suppliers in the die-casting industry, it has benefited from strong demand for precision-engineered metal parts. Many die-casting companies have invested in advanced machinery and automation to meet the stringent quality requirements of the automotive industry. Since electric vehicles are becoming more popular The industry is evolving to create specialized die-cast components that include battery casings and motor housings and light structural elements.

Die casting also plays a significant role in the electronics and telecom industries of Malaysia, where precision and dependability are crucial. The country is a major exporter of electronic components supplying global brands with high-quality aluminum enclosures, heat sinks and connectors. The ability of die casting to produce complex shapes that have tight tolerances allows it to produce the components that can be seamlessly integrated into various electronic devices. Many Malaysian die-casting firms work with tech companies to create specific solutions to smartphones, laptops as well as data centers as well as telecommunications equipment. As the growth continues in the digital economy, demand for advanced die-cast components will likely to increase. The companies are working on enhancing the electrical shielding, thermal conductivity, and lightweight properties to enhance the performance of electronic components. The integration of automation and intelligent manufacturing processes can further improve productivity in the manufacturing of precision metal components.

Sustainability has been a key focus in Malaysia's die-casting industry, with companies adopting eco-friendly production methods to reduce their environmental impact. Utilizing recyclable products, efficient production techniques, and waste reduction strategies has gained momentum, driven by regulatory demands and consumer demand for sustainable products. Numerous manufacturers have adopted closed loop recycling methods, which allow them to repurpose scrap metal, and decrease reliance on the raw materials. Furthermore, advances in the field of filtration and emission control technology have reduced the carbon footprint of die casting facilities. Government incentives promoting sustainable manufacturing have prompted businesses to invest in cleaner technology, while ensuring that they are in line to international standards for sustainability. With the world's industries moving towards carbon-free production, Malaysia's dedication to sustainable die casting will be crucial to keeping the edge it has within the global marketplace. To find further details kindly head to Senadiecasting

The adoption of cutting-edge technology has played a vital contribution to the growth of Malaysia's die casting industry, allowing manufacturers to improve precision, efficiency, and scalability. Computer-aided designing and simulation software permits companies to optimize mold designs which reduces production mistakes and the waste of materials. Automation and robotics within die-casting processes has increased productivity while ensuring consistency in the quality of manufacturing at large scale. Industry 4.0 technologies, such as real-time data monitoring, the Internet of Things , and artificial intelligence are enhancing process control and predictive maintenance. These advances aid in helping Malaysian die-casting companies keep their competitive edge in an ever technologically advanced manufacturing. Through continuous investment in research and development, Malaysia is strengthening its reputation as a high-tech manufacturing hub that can meet the requirements of precise engineering across multiple industries.

As we look to the future, Malaysia's die-casting industry will likely to witness an impressive growth spurred by sustainability, innovation increasing demands for high-quality metal parts. The government and industry leaders are working together to enhance efforts to research and develop that encourage the implementation of advanced materials and new casting methods. Training programs for workers are being introduced to equip professionals with the required skills in operating modern die-casting equipment and automated systems. As industries such as electric vehicles, renewable energy and intelligent technology continue to expand, the die-casting industry in Malaysia is well-positioned to meet the increasing need for high-performance metal parts. A strong infrastructure for manufacturing in the country, coupled with its commitment to sustainable development and technological innovation will ensure that Malaysia continues to be a leading participant in the worldwide die-casting marketplace. By implementing continuous improvement and strategic investments, the sector will continue to drive development while preserving its status as an institution of quality manufacturing.